- Africa and Europe

White sugar ICUMSA 45 is a highly refined sugar grade, known for its sparkling white color and purity, commonly produced in Brazil, which is one of the world’s leading sugar producers.

ICUMSA is an acronym for the

International Commission for Uniform Methods of Sugar Analysis,

and the number 45 signifies the level of purity of the sugar.

The integrated steps of growth, harvest, production, and transport work in sync to establish Brazil as a powerhouse in the global sugar market, especially for white sugar ICUMSA 45. With its strategic location and investment in infrastructure, Brazil successfully continues to meet the massive global demand for this sweet commodity.

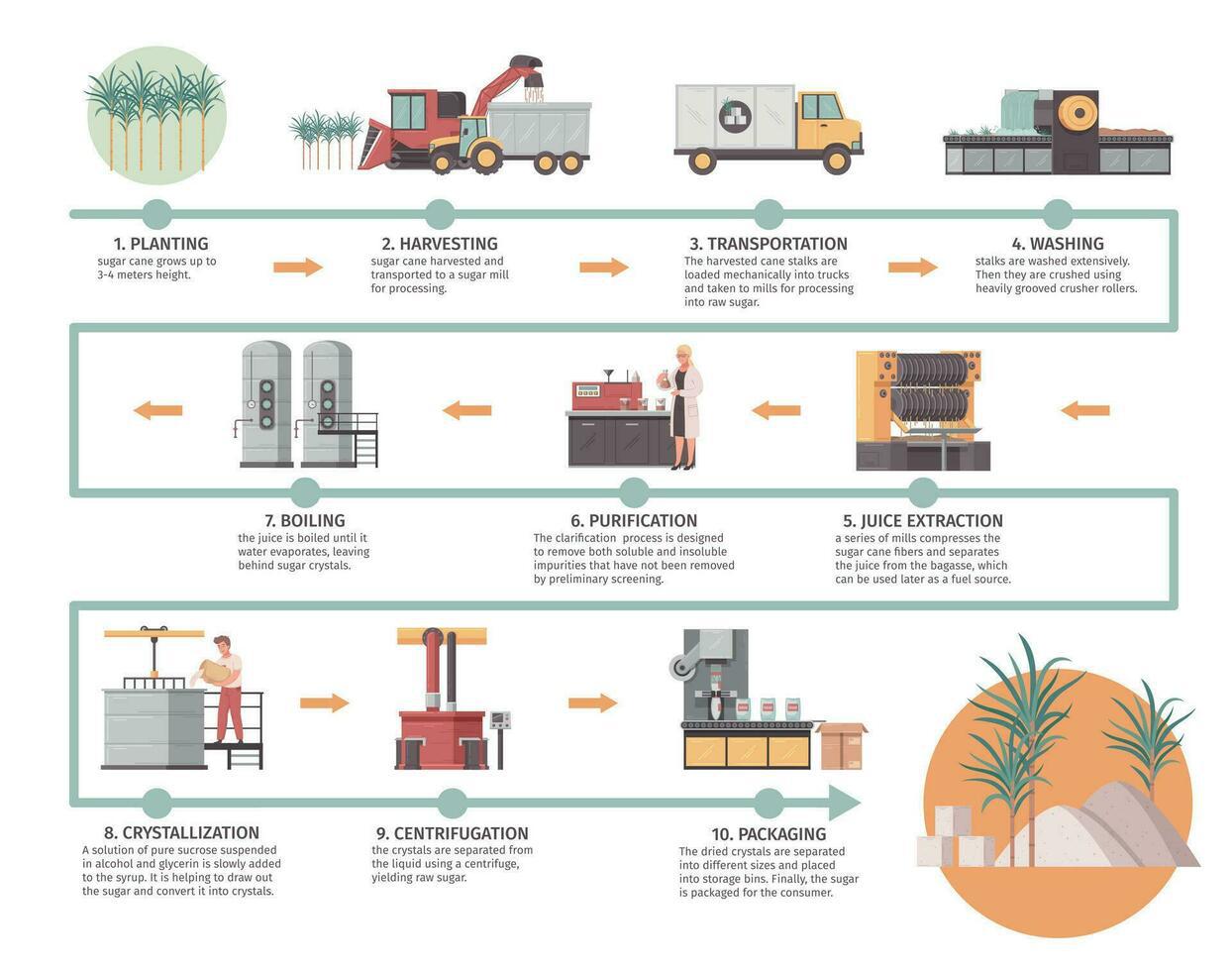

In Brazil, sugar cane planting usually takes place at the onset of the rainy season. The optimal conditions for sugar cane are tropical climates with well-distributed annual rainfall. The planting involves preparing the field, which often requires tilling the soil to eliminate weeds and laying down sugar cane cuttings, typically pieces from mature cane stalks that have at least one “eye” or bud from which the new plant can grow. Farmers use both traditional and modern agricultural practices. In some cases, sugar cane is still planted manually, but increasingly, the process is mechanized. Sugar cane is a perennial crop which means that once planted, it can be harvested several times before replanting is necessary. It usually matures in a cycle of 12-18 months.

When the cane is ready for harvesting, the fields are often burned to remove the dry leaves without damaging the stalks. This process also helps eradicate pests and snakes. However, the trend towards more sustainable environmental practices has led to the increased use of “green harvesting,” where there is no pre-harvest burn.

Harvesting can be done manually with machetes in smaller farms or by using mechanical harvesters that cut the cane just above the root. The harvested cane must be processed quickly to prevent sugar degradation.

Once cut, the sugar cane is promptly transported to sugar mills. Transportation is usually done using trucks or tractors, and the distance from field to factory is commonly kept short to reduce costs and prevent spoilage.

At sugar mills, the sugar cane undergoes a series of processes

1. Crushing : The cane is crushed to extract the juice.

2. Purification : The juice is then purified using lime and heat which helps to remove impurities and clarify the juice.

3. Evaporation : The purified juice is concentrated by boiling under a vacuum in large evaporators to remove water and create a sugar syrup.

4. Crystallization : The syrup is further evaporated until crystals begin to form and then it is spun in centrifuges to separate the crystals from the remaining liquid (molasses)

5. Drying : The sugar crystals are then dried to prevent clumping.

6. Refining : For ICUMSA 45, additional refining is carried out to achieve the high level of purity and the white color desired. This includes washing, filtration, and other treatments to remove any remaining impurities.

After refining, the sugar ICUMSA 45 is packaged, often in 50 kg bags, and made ready for export. Quality control is critical throughout the process to ensure the product meets international standards.

The packaged sugar is sent to collection centers and then transported to the nearest port. The transportation within Brazil is usually by road, but rail is also used, especially over longer distances to the ports. Brazil’s vast coastlines and well-developed infrastructure facilitate the efficient movement of sugar to ports where it is stored in warehouses before being loaded onto cargo ships for export.

Sugar is loaded in bulk or in containers onto vessels, often using conveyor systems for bulk shipments, and is then shipped to various international destinations.

Brazil has several ports that handle sugar exports, including the Port of Santos, which is one of the largest and busiest in Latin America.

The Santos Port is a pivotal asset for the sugar industry, known for its substantial capacity and remarkable efficiency. As one of the largest and most efficient ports in the world, Santos Port plays a critical role in the global sugar trade. Its expansive infrastructure and advanced handling capabilities ensure swift and seamless movement of sugar products, facilitating large-scale exports and imports with precision and reliability. With its strategic location and state-of-the-art facilities, Santos Port stands as a beacon of efficiency, serving as a key enabler for the sugar industry’s growth and success on an international scale.

Product |

45RBU (REFERENCE BASE UNIT) |

|---|---|

|

ORIGIN |

BRAZIL |

|

ICUMSA |

45 RBU ICUMSA, ATTENUATION INDEX UNITS METHOD 10-1978 |

|

ICUMSA |

45 RBU ICUMSA, ATTENUATION INDEX UNITS METHOD 10-1978 |

|

POLARIZATION AT 20 C |

99.80% MINIMUM |

|

MOISTURE |

00.04% MAXIMUM |

|

SULPHATED ASH CONTENT |

00.04% MAXIMUM |

|

SO2 |

20PPM |

|

GRANULATION |

FINE STANDARD |

|

SOLUBIKITY |

100% DRY AND FREE FLOWING |

|

RADIATION |

NORMAL WITHOUT PRESENCE OF CESIUM OR IODINE SO2: CERTIFIED |

|

COLOR |

CRYSTAL WHITE |

|

SMELL |

FREE OF ANY SMELL |

|

MAGNETIC PARTICLES |

MG/K4 |

|

SOLUBILITY |

MG/K20 |

|

Max AS |

1.P.P.M |

|

Max OS |

2.P.P.M |

|

Max CU |

3.P.P.M |

|

REDUCINF SUGAR |

0.010% MAXIMUM IN DRY MASS |

|

HPN STAPH AUREUS |

PER 1G- NIL |

|

MICRBIOLOGICAL LIMITED |

PATHOGENIC BACTERIA INCLUDING SALMONELLA PER 1G - NIL BACILLUS PER 1G - NIL |

|

SUBSTANCE |

SOLID CRYSTAL |

|

TRACE PESTICIDE |

MAX. MG/KG BASE - DDT 0.005-PHOTOXIN 0.001-HEXACHLORAN-GAMMA ISOMER 0.005 |

We take pride in offering the best rates, ensuring superior quality, and guaranteeing accuracy in delivery. Our commitment to excellence extends beyond just a promise; it is our standard. In addition to providing top-notch products, we understand that financing plays a crucial role. That’s why we are here to assist in financing orders, ensuring a seamless transaction process. With a global reach, we are prepared to deliver worldwide, making accessibility a priority. Partner with us for a reliable and trustworthy experience, where value, quality, and customer satisfaction are at the forefront of our service.

Printo General Trading LLC, a leading multi-trade organization based in Dubai, UAE, with a global presence. Specializing in essential goods and renowned brands, we bridge gaps and deliver excellence across multiple industries worldwide.